Email:sales@jpskcnc.com

Skype/Whatsapp/Mob:+86 13853189175

Product description:

This series CNC busbar processing machine has three units: punching shearing and bending. It is easy to adjust each unit to shorten the processing time and improve the production efficiency.

The bending unit uses the imported PLC control system, which has a stable system and high precision. It is used to process copper and aluminum busbars in different specification. By relative operation unit it can and quickly do all kinds of processing to copper and aluminum Busbar, such as shearing, punching(circular hole and oblong hole), flat/Vertical bending and knurling.change different mold to do special processing to copper bar, such as flat press, embossing, cable connector process, and can do cutting,flat Crushing pushing and bending.

Function

|

Model

|

JPMX-303ESK

|

JPMX-503ESK

|

JPMX-803ESK

|

Punching

|

Max.punching force(kn)

|

300

|

500

|

800

|

Punching diameter range(mm)

|

4.3-25

|

4.3-30

|

4.3-30

| |

Max.thickness(mm)

|

12

|

16

|

20

| |

Max.width(mm)

|

160

|

200

|

250

| |

Shearing/Cutting

|

Max.shearing thickness(mm)

|

12

|

16

|

20

|

Max.shearing width(mm)

|

160

|

200

|

250

| |

Horizontal bending

|

Max.bending force(kn)

|

300

|

500

|

800

|

Max.width(mm)

|

160

|

200

|

250

| |

Max.thickness(mm)

|

12

|

16

|

20

| |

Horizontal bending

|

Max.width(mm)

|

100

|

120

|

120

|

Min.angle(Degree)

|

90°

|

90°

|

90°

| |

Out dimension

|

mm

|

1780*1380*1420

|

1850*1500*1550

|

1850*1500*1600

|

Power

|

kw

|

3x4kw

|

3x5.5kw

|

3x5.5kw

|

Weight

|

Kg

|

1400kg

|

1950kg

|

2350kg

|

CNC precision

|

Bending precision

|

±1°

|

±1°

|

±1°

|

Repeat bending precision

|

±0.3

|

±0.3

|

±0.3

|

Main Features:

The shearing unit adopts the universal frustration shearing, the cutting is smooth without burrs, the appearance is beautiful, and the cutting is free of waste.

The punching unit uses a united six-mode turnplate in tooth shape to make sure the upper mold and the lower mold are absolutely in the center, improve the mold concentricity and extend the working life.

The turnplate is in tooth shape with a good view and high strength. No need to frequent change molds, labor intensity is highly reduced. It is easy and quick to use. Producing efficiency is obviously higher than a traditional one.

The bending unit uses a double-decker working table, which can make sure that three working positions can do their respective at the same time without bothering the others. By changing different mold it can do flat bending and verticle bending. Input an busbar thickness and an angle on a Controller touching screen, or input height and a side length to get the result what you need, such as Z bending. Bending precision is ±1,repeat precision ±0.3 .

The user can input processing data in advance, and the system will do the process according to the rebound data. The field data can be put into the system at any time and paged out for using repeatedly.

The machine has four casters so it is easier to be moved everywhere. There are two operating modes, manual button, and footswitch, which is easy for a worker to operate and use. Based on the user's requirement, it can do all kinds of special Shape processing with different molds or equipping parts.

The shearing unit adopts the universal frustration shearing, the cutting is smooth without burrs, the appearance is beautiful, and the cutting is free of waste.

The punching unit uses a united six-mode turnplate in tooth shape to make sure the upper mold and the lower mold are absolutely in the center, improve the mold concentricity and extend the working life.

The turnplate is in tooth shape with a good view and high strength. No need to frequent change molds, labor intensity is highly reduced. It is easy and quick to use. Producing efficiency is obviously higher than a traditional one.

The bending unit uses a double-decker working table, which can make sure that three working positions can do their respective at the same time without bothering the others. By changing different mold it can do flat bending and verticle bending. Input an busbar thickness and an angle on a Controller touching screen, or input height and a side length to get the result what you need, such as Z bending. Bending precision is ±1,repeat precision ±0.3 .

The user can input processing data in advance, and the system will do the process according to the rebound data. The field data can be put into the system at any time and paged out for using repeatedly.

The machine has four casters so it is easier to be moved everywhere. There are two operating modes, manual button, and footswitch, which is easy for a worker to operate and use. Based on the user's requirement, it can do all kinds of special Shape processing with different molds or equipping parts.

Processing details

THE CORNER OF THE WORKSHOP

https://www.youtube.com/watch?v=Jg_CpNlbHCE

Jingpeng CNC has passed the 15 years of copper bus processing industry R&D, We have established trade relations with more than 100 countries and regions around the world.

Our advantage:

1.Warranty : one year guarantee for whole machine (not including spare part)

2.Our PLC are from Siemens.

3.Our thermal relays, AC contactors, circuit breakers are from Schneider.

4.We are factory. we can do OEM as per clients request.

5.We have strong after-sales services team and professional technicians who can gurantee professional guidance after sales.

6.With Certification of CE&ISO 9001 .

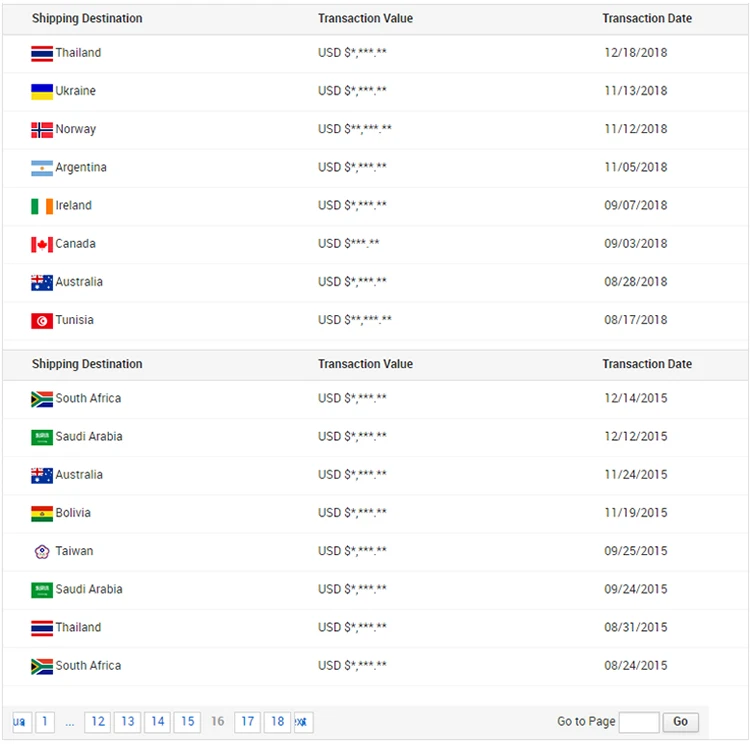

Some record of the transaction by Trade Insurance as follows:

1.Warranty : one year guarantee for whole machine (not including spare part)

2.Our PLC are from Siemens.

3.Our thermal relays, AC contactors, circuit breakers are from Schneider.

4.We are factory. we can do OEM as per clients request.

5.We have strong after-sales services team and professional technicians who can gurantee professional guidance after sales.

6.With Certification of CE&ISO 9001 .

Some record of the transaction by Trade Insurance as follows:

FAQ

1. What is your payment terms:

1. What is your payment terms:

40% TT as deposit, balance be paid when goods are ready for loading before shipment.

2. What is your power supply?

We will adjust according to your countries power supply. No problem.

3. What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

4. If I buy your CNC busbar processing machine, will you offer me PLC backup?

Yes, we will.

5. Are all the Labels and instuctions of the machine in English?

Yes. the labels on the machine and the manuel books are all made in english version.

6. Besides this machine, do you have any other options for me?

We have dozens of options for you:

CNC busbar machine; non- CNC busbar machine, combined busbar machine, busbar cutting tools, busbar bending tools, busbar punching tools.hydraulic pumps, hand pumps etc.